[Super Abrasive]

Bite

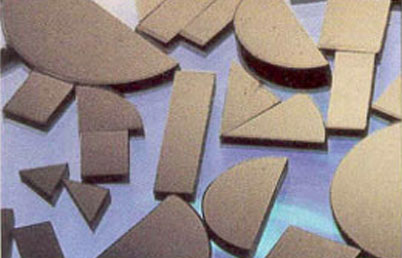

PCD, PCBN cutting tool

※ You can check the contents by scrolling left / right.

Plate Type & Purpose

| PCD Cutting Tool | PCBN Cutting Tool | |

|---|---|---|

| It is a strong compound sinterring a diamond particle under high temperature& pressure. It has no direction and has all of hardness, the abrasive Wear Resistance and Thermal Conductive diamond has | it is compound sinterring CBN particle, which doesn't react to with ferreous metal, under ultra high temperature · pressure and used in a hard ferreous matter | |

| Use | Efficiency at part cutting processing nonferreous metal like aluminum, copper alloy as hard metal | Fitness for cutting processing of heat treatment steel, sintering ally iron, Thermal spray metal, difficult-to-cut materials like heat resisting alloy |

| Feature | - Little is chipping production - Though cut different thing like hard, edge's damage is little and there isn't formation of phosphoric -for tool longevity is 30~100 as long as hard metal, losetime replacing a tool is little and machine's operating ratio improvement. -A size compensation of a tool abrasion is little. -a tool cost is inexpensive. |

- High speed cutting of a hard metal by 10times - Efficiency of a processing cost reducing by tool cost's reduction and cutting ability's improvement - Predictors of dimension is improved and can gain clean agressive stock removal surface, so it is possible to turn grinding processing into cutting processing - Tool's fintion is improve by using a cutting fluid |

* We sell material and specially manufacture by spec.